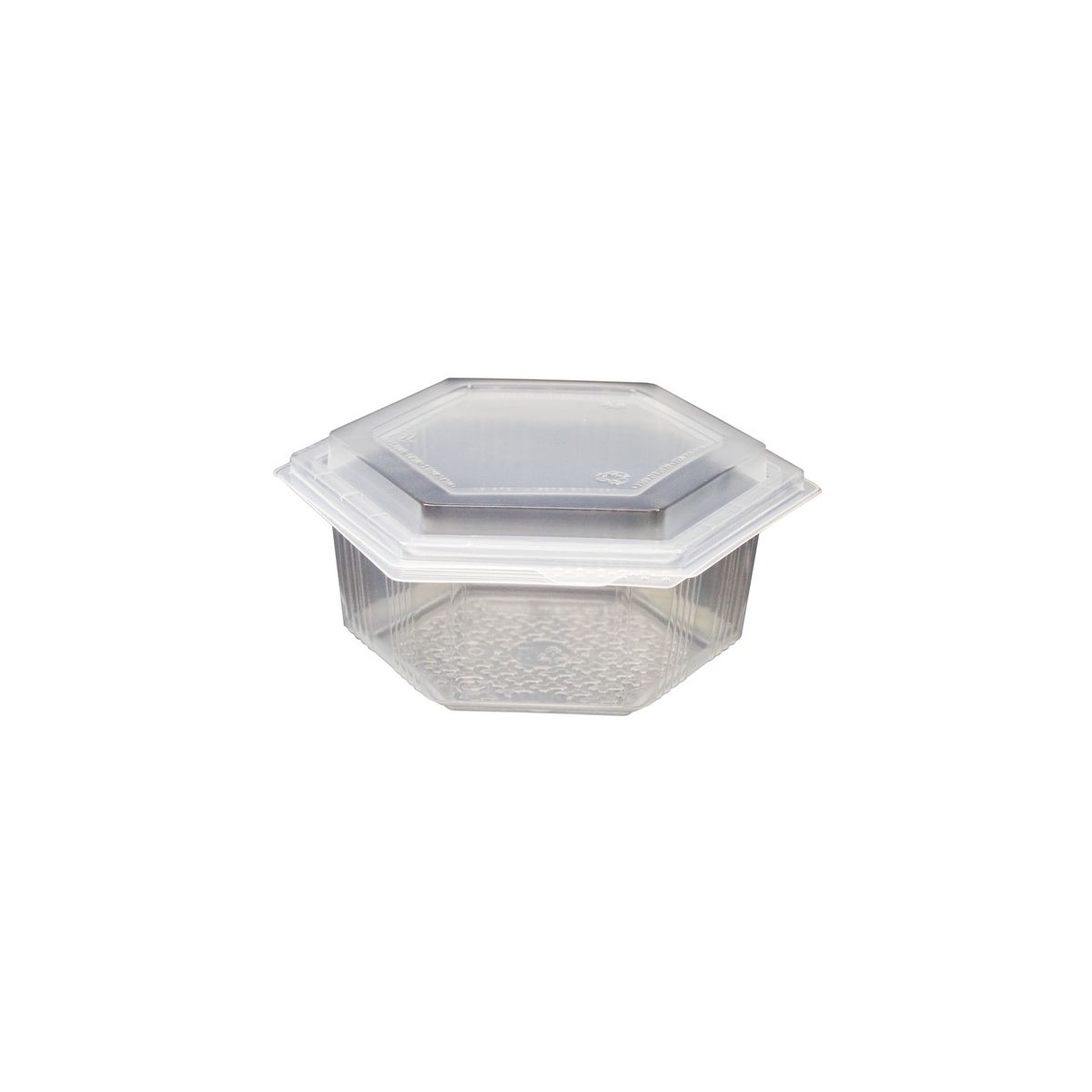

Embalagem Micro-ondas em BDP PP translúcido Hexagonal M5100 500g 160x151x76mm Caixa 600

- Integralmente reciclável

- Biodegradável

| Características | |

|---|---|

| Código | 0412993 |

| Embalagem | 600un |

| Material | BDP PP |

| Cor | Translúcido |

| Dimensões | 160x151x76mm |

| Capacidade | 500g |

Documentos

Detalhes

O que são o “BDP PP e BDP PET”?

O “BDP PET e BDP PP” consistem em novos materiais plásticos revolucionários integralmente recicláveis e biodegradáveis*.

Os ensaios a que estes materiais foram submetido corroboram de forma inequívoca estas incríveis potencialidades.

Porque motivo se considera o “BDP PP e BDP PET” como materiais revolucionários?

Ensaios realizados no passado comprovam que alguns materiais biodegradáveis em condições específicas, como, por exemplo, o ácido poliláctico (PLA), não são recicláveis quando integrados nos circuitos de reciclagem actualmente existentes na Europa. Com efeito, estes materiais são inclusivamente considerados como agentes contaminantes dos plásticos recicláveis.

O carácter revolucionário e inovador do “BDP PP e BDP PET” reside no facto de serem 100% recicláveis nas cadeias de reciclagem Europeias e de serem biodegradáveis* quando eventualmente atingem o fim do seu ciclo de vida útil. O custo destes produtos é inferior ao de outros materiais que reivindicam ter propriedades semelhantes.

Existe algum constrangimento na utilização do “BDP PP e BDP PET”?

A inevitável resistência e relutância perante a utilização deste novo material que possui um custo acrescido constitui actualmente a única limitação à utilização generalizada do “BDP PP e BDP PET” na indústria dos plásticos. Não obstante, uma gestão equilibrada no consumo deste produto permite reduzir os gastos.

O “BDP PP” e o PP são materiais compatíveis?

As características do “BDP PP” são idênticas às do PP convencional utilizado na produção de embalagens e de outros materiais e objectos destinados a contacto com géneros alimentícios, nomeadamente no que concerne à transparência e às propriedades mecânicas. Por este motivo, existe uma total compatibilidade na utilização conjunta e simultânea de ambos os materiais no fabrico de qualquer produto.

O mesmo se pode dizer do BDP PET e a sua utilização com RPET.

Anualmente biliões de embalagens plásticas são depositadas em aterros sanitários ao invés de serem recicladas após uso.

A utilização do “BDP PET e BDP PP” no fabrico de embalagens plásticas constitui uma solução viável quando estas atingem o fim do seu ciclo de vida útil pois permite que a sua decomposição ocorra naturalmente em poucos anos ao invés de se prolongar por vários séculos.

Utilizado industrialmente na produção de embalagens plásticas por termoformagem, o “BDP PP e BDP PET” são filmes plásticos integralmente recicláveis e biodegradáveis*. A biodegradabilidade deste material inovador foi corroborada através de ensaios realizados de acordo com a norma ASTM D5511. Neste método de teste padrão, aplicado na determinação da biodegradação anaeróbia de materiais plásticos sob condições de digestão anaeróbia de elevado conteúdo sólido, recorre-se geralmente a um conteúdo de material sólido de 50%. As condições de humidade características dos aterros mais húmidos oscilam entre os 55% e os 65%, podendo atingir os 93% no caso de aterros mais secos.

As actuais taxas de biodegradação plástica em aterros sanitários biologicamente activos variam de acordo com o tipo de material plástico e a configuração do produto, assim como em função do conteúdo sólido, temperatura e teor de humidade do aterro.

A abordagem à temática dos plásticos biodegradáveis pressupõe uma compreensão do conceito de “processo de biodegradação”, o qual tem sido alvo de uma incorrecta utilização e interpretação. Os plásticos que sofrem fragmentação ou degradação através de reacções químicas, por influência da radiação ultravioleta e/ou por acção de processos mecânicos não são considerados biodegradáveis. Com efeito, estes materiais sofrem uma mera degradação, gerando toxinas, metais pesados, resíduos plásticos e outras substâncias que se acumulam no meio ambiente.

Os plásticos são hidrocarbonetos produzidos a partir do petróleo, um composto orgânico natural 100% biodegradável por acção de bactérias. Durante o seu processo de destilação, que decorre a altas temperaturas, os nutrientes orgânicos originais são volatilizados. Os produtos plásticos são concebidos para serem duráveis e, no caso das embalagens, para conferirem uma protecção eficaz aos materiais embalados. Por este motivo, são necessárias centenas de anos para que os microorganismos decomponham os plásticos tradicionais em biogás e biomassa.

Muitas das vantagens dos produtos plásticos convertem-se em desvantagens quando se torna necessário descartá-los após o fim da sua vida útil. Ao invés de serem reutilizados ou reciclados, a grande maioria destes produtos são eliminados como resíduos no lixo, sendo posteriormente depositados em aterros sanitários. Com efeito, cerca de 79% da totalidade dos plásticos fabricados até à data foram enviados para aterro. A reciclagem continua a revelar-se um desafio económico e logístico. O plástico tende a ser reciclado uma única vez e posteriormente processado em tecido ou madeira sem possibilidade de reciclagem subsequente. É por este motivo que a generalidade do plástico, inclusivamente os plásticos recicláveis, é descartada em aterro.

* Requisito de tempo em que os materiais são descartados e o tipo, quantidade e qualidade dos microrganismos presentes. Testamos embalagens de PP via ASTM D5511 e obtivemos biodegradação de 8,88% após 30 dias, embalagens em PET obtiveram uma biodegradação de 11.68% após 30 dias.

-

Biodegradável

Quando os deita no lixo, os produtos biodegradáveis podem ser decompostos por microorganismos biológicos, sem prejudicar o meio ambiente.

-

Reciclável

Este produto pode ser reciclado e mais tarde transformado noutro produto

Outros Produtos da mesma linha

-

Embalagem Micro-Ondas em BDP PP translúcido M5200 650cc 372un

Código 0412990

82,58€/CAIXA 600

IVA e Taxas legais não incl.

-

Embalagem Micro-Ondas em BDP PP translúcido M5300 1210cc 360un

Código 0412991

102,08€/CAIXA 600

IVA e Taxas legais não incl.

-

Embalagem Micro-Ondas em BDP PP translúcido M5500 2700cc 120un

Código 0412992

80,41€/CAIXA 600

IVA e Taxas legais não incl.

-

Embalagem Micro-ondas em BDP PP translúcido Hexagonal M5000 250g 160x151x47mm Caixa 600

Código 0412994

111,39€/CAIXA 600

IVA e Taxas legais não incl.

-

Embalagem Micro-Ondas em BDP PP translúcido M5400 1210cc 150un

Código 0412995

93,48€/CAIXA 600

IVA e Taxas legais não incl.

-

Saladeira com Tampa em PLA transparente 530ml 18oz 150un

Código 0410511

64,61€/CAIXA 600

IVA e Taxas legais não incl.

-

Saladeira com Tampa em PLA transparente 710ml 24oz 150un

Código 0410512

101,23€/CAIXA 600

IVA e Taxas legais não incl.

-

Saladeira com Tampa em PLA transparente 940ml 32oz 150un

Código 0410513

109,52€/CAIXA 600

IVA e Taxas legais não incl.

-

Saladeira com Tampa em PLA transparente 1420ml 48oz 150un

Código 0410514

130,26€/CAIXA 600

IVA e Taxas legais não incl.

PT - Português

PT - Português ES - Español

ES - Español EN - English

EN - English FR - Français

FR - Français PT - Português

PT - Português ES - Español

ES - Español EN - English

EN - English FR - Français

FR - Français